Industrial paint: Extend the life of your equipment

Industrial paint: Extend the life of your equipment

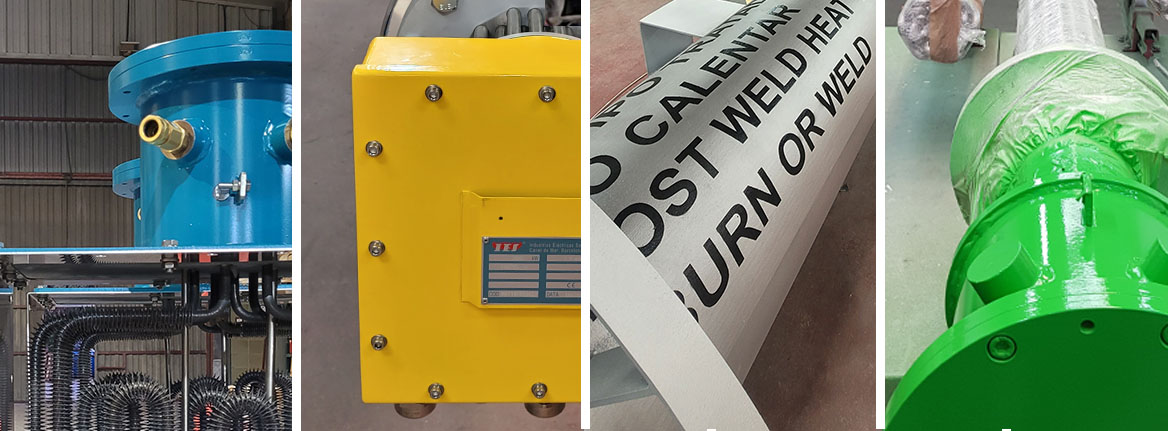

We talk about high-temperature industrial paint and anti-corrosion systems.

In any industrial facility, protecting equipment does not depend only on thermal efficiency. Exposure to humidity, chemical agents and oxidation means that materials, especially carbon steel, need additional defence. This is where high-temperature industrial paint and anti-corrosion systems come into play, regulated by the ISO 12944 standard, which sets categories and criteria for selecting the right coating.

What is high-temperature paint?

High-temperature paint is a technical coating designed to protect metal surfaces that operate under extreme conditions, whether due to heat, chemical aggressiveness or marine and industrial environments. Unlike conventional paint, these formulations withstand temperatures of up to 400 °C or more, depending on their composition (epoxy, silicone, polysiloxanes, etc.).

Why is it necessary?

Why is it necessary?

Carbon steel, widely used in industry, is especially vulnerable to corrosion. If untreated, contact with oxygen and moisture produces rust, reducing its service life. Paint acts as a protective barrier, preventing direct contact with the environment and extending equipment durability. By contrast, stainless steels usually do not require paint, since their own passive layer already protects them.

According to ISO 12944, appropriate protection depends on the corrosivity of the environment: a warehouse interior in a rural area (C2) is not the same as a petrochemical plant in a marine environment (C5-M).

Classification according to ISO 12944

The standard defines categories from C2 to C5:

- C2 (low corrosion): interiors with occasional condensation or exteriors in mildly aggressive rural areas.

- C3 (medium): urban or industrial areas with some pollution and humidity.

- C4 (high): industrial or coastal environments with medium salinity, such as chemical plants or indoor swimming pools.

- C5-I and C5-M (very high): industrial environments with high humidity (C5-I) or marine areas with high salinity (C5-M).

The higher the category, the more demanding the paint system is in terms of preparation, coats and applied thickness.

The role of surface preparation

Before painting, the metal must be in optimal condition. ISO 8501-1 defines different degrees of cleanliness, ranging from manual scraping to abrasive blasting Sa 3 (white metal, completely clean). This stage is key: without a well-prepared surface, the paint loses adhesion and protection is drastically shortened.

Coats and paint thicknesses

An industrial paint system is not a single coat, but a combination of several:

- Primer: ensures adhesion and provides initial protection.

- Intermediate coats: reinforce mechanical and chemical resistance.

- Top coat: provides the finish and acts as the outer shield.

Depending on the corrosivity category, between 2 and 4 coats may be applied, with thicknesses ranging from 120 to 300 microns or more in aggressive marine or industrial environments.

Common applications

High-temperature paint systems are common in sectors such as:

- Petrochemical and oil & gas: piping, tanks and structures exposed to heat and chemical agents.

- Chemical industry: equipment in contact with corrosive substances.

- Energy and thermal processes: furnaces, boilers and heat exchangers.

- Marine infrastructure: offshore platforms and ports, where salinity accelerates corrosion.

Quality control

To ensure the paint system has been applied correctly, tools such as a gauge are used to measure the thickness of each coat. In this way, it is verified that the minimum thickness set by the standard or manufacturer has been reached. It is also important to respect drying and curing times between coats.

Benefits for the client

Benefits for the client

Investing in a good industrial paint system brings clear benefits:

- Durability: extends equipment service life, reducing failures.

- Safety: prevents leaks or structural damage due to corrosion.

- Cost savings: less maintenance and replacement.

- Sustainability: less waste and less need to manufacture new parts.

High-temperature paint and systems regulated by ISO 12944 are essential tools to ensure that carbon-steel industrial equipment can withstand decades in harsh environments.

At IES Soler, we supervise rigorous processes and control tools to ensure that each piece of equipment is protected with the best coatings, considering its durability and optimising costs for the client.